MARKETS

Strip & Finned Strip Heaters

PRODUCTS

- Backer Hotwatt

- / Our Products

- / Strip and Finned Strip Heaters

STRIP & FINNED STRIP HEATERS

Availability: In Stock

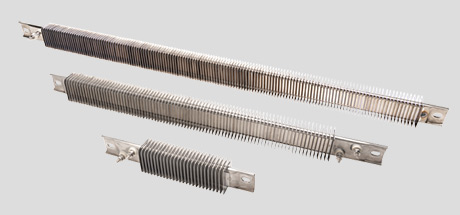

STRIP HEATERS: CERAMIC INSULATED

Description

Applications

Dies, Molds, Plastic Forming and Sealing, Tank and Kettle Heating. For specific applications, correctly rated elements should be used to prevent overheating and to ensure long life. A guide to correct watt densities for specific applications is shown below.

Features

- The Backer Hotwatt Stainless Steel Strip Heater provides clean, dependable heat with sheath temperatures up to 1200°F and watt densities up to 40 watts per square inch.

- Because of the seamless stainless steel sheath, Backer Hotwatt Ceramic Insulated Strip Heaters are dimensionally stable in milled slots.

- Made in U.S.A

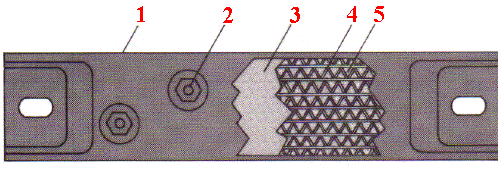

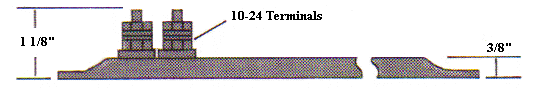

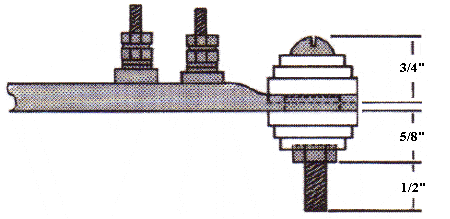

Construction

- Seamless stainless steel sheath.

- Post terminals.

- Ceramic element support.

- Element wire situated in close proximity to outside surface for maximum heat transfer and minimum internal temperature while preserving good dielectric qualities.

- Magnesium oxide packing.

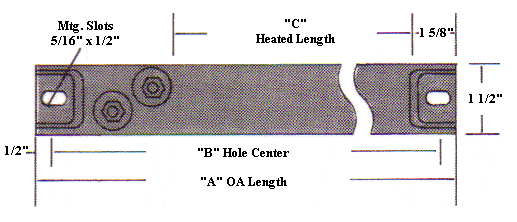

Catalog Number | “A” | “B” | “C” | Min. Watts | Max. Watts |

|---|---|---|---|---|---|

CS-5.5 | 5 1/2″ | 4 1/2″ | 1″ | 50 | 180 |

CS-7.5 | 7 1/2″ | 6 1/2″ | 3″ | 50 | 360 |

CS-8 | 8″ | 7″ | 2 3/4″ | 50 | 430 |

CS-9.5 | 9 1/2″ | 8 1/2″ | 4 1/4″ | 50 | 510 |

CS-10.5 | 10 1/2″ | 9 1/2″ | 5 1/4″ | 50 | 630 |

CS-12 | 12″ | 11″ | 7 1/4″ | 50 | 810 |

CS-14 | 14″ | 13″ | 9 1/4″ | 50 | 1050 |

CS-15.2 | 15 1/4″ | 14 1/4″ | 10″ | 50 | 1200 |

CS-16.2 | 16 1/4″ | 15 1/4″ | 11″ | 50 | 1320 |

CS-18 | 18″ | 17″ | 12 3/4″ | 50 | 1530 |

CS-19.5 | 19 1/2″ | 18 1/2″ | 14 1/4″ | 50 | 1710 |

CS-21 | 21″ | 20″ | 15 3/4″ | 50 | 1890 |

CS-23.7 | 23 3/4″ | 22 3/4″ | 18 1/2″ | 50 | 2220 |

CS-25.5 | 25 1/2″ | 24 1/2″ | 20 1/4″ | 50 | 2430 |

CS-26.7 | 26 3/4″ | 25 3/4″ | 21 1/2″ | 50 | 2580 |

CS-28.2 | 28 1/4″ | 27 1/4″ | 23″ | 75 | 2760 |

CS-30 | 30″ | 29″ | 24 3/4″ | 75 | 2970 |

CS-30.5 | 30 1/2″ | 29 1/2″ | 25 1/4″ | 75 | 3030 |

CS-33.5 | 33 1/2″ | 32 1/2″ | 28 1/4″ | 75 | 3390 |

CS-35.7 | 35 3/4″ | 34 3/4″ | 30 1/2″ | 75 | 3660 |

CS-38.5 | 38 1/2″ | 37 1/2″ | 33 1/4″ | 100 | 3990 |

CS-42.5 | 42 1/2″ | 41 1/2″ | 37 1/4″ | 100 | 4320 |

CS-47.7 | 47 3/4″ | 46 3/4″ | 42 1/2″ | 100 | 4320 |

CS-50.5 | 50 1/2″ | 49 1/4″ | 45 1/4″ | 100 | 4320 |

CS-53.7 | 53 3/4″ | 52 3/4″ | 48 1/2″ | 100 | 4320 |

CS-63.7 | 63 3/4″ | 62 3/4″ | 58 1/2″ | 100 | 4320 |

Red catalog number denotes stock item. See stock section for specific ratings.

- Maximum wattage limited by 18 amp maximum at 240 volts for catalog numbers CS-42.5 and longer. Any wattage is available between minimum and maximum without effecting price.

- Unit lengths between and longer than those listed may be ordered.

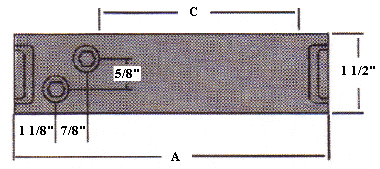

- Standard termination is Type OF. Units under 8″ long, standard termination is Type SSA.

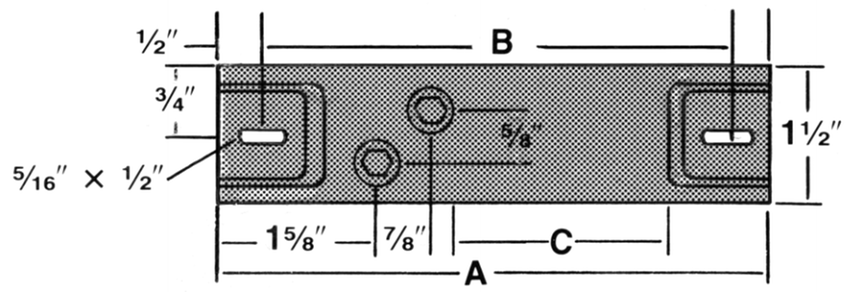

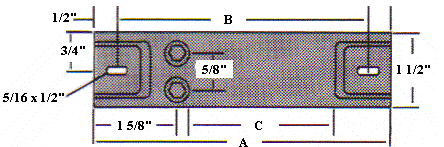

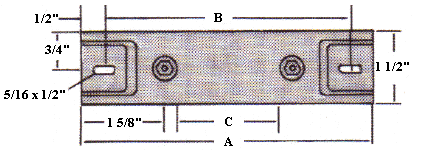

Standard Termination

Type OF: Offset at one end.

Application | Max.Watts/sq.in. |

|---|---|

Platen heating | |

Up to 300°F | 40 |

300° – 600°F | 20 |

600° – 800°F | 15 |

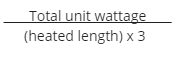

Formula for Determination of Watt Density

Watts/sq.in. =

Optional Terminations

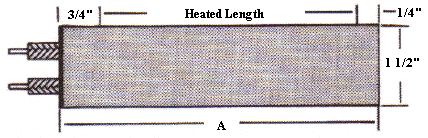

Type SSA: Parallel at one end. Heated length (“C”) is 3/4″ longer.

Type SO: One each end. Heated length (“C”) is 1″ shorter.

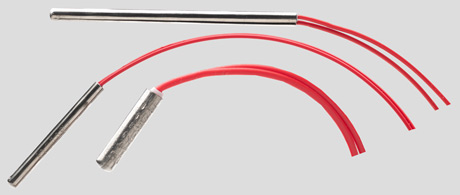

Type SF1: Flexible high temperature insulated leads. Specify length. Opposite end of unit may be standard closure with mounting hole or any of the optional closures. (Blunt end, XS54, shown) Suitable for use to 480V. Lead end may be sealed for moisture resistance.

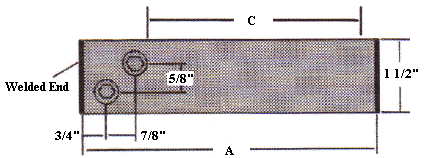

Optional End Closures

XS-54:Blunt end. Welded each end with no mounting holes. May be used with Type OF, SSA, or SO terminals. Heated length (“C”) is 3″ longer.

XS-83:Short crimp. At each end with no mounting holes. May be used with Type OF, SSA, or SO terminals. Heated length (“C”) is 1″ longer.

XS-84: Secondary insulating bushings. Required when units are connected in series on voltages above 300V. Sheath must be isolated. Requires enlarged (1/2″ x 3/4″) mounting hole each end. May be used with Type OF, SSA, or SO terminals.

Tolerances

Width: 1.500, ±.020

Length: Up to 24″, ±1/16″ 24″ and over, ±1/8″

Thickness: .375, ±.020

Wattage tolerances are held to +5%, -10% at rated voltage.

Voltage

Standard voltages are either 120sV or 240V. Other voltages are available.

How to Order

After determining the wattage required and the line voltage available, determine the physical space available for heaters and the number of heaters required. Review Strip Heaters In-Stock.

Specify: Catalog number, wattage, voltage, termination, and special features if required.

Example: CS12/250W/120V/OF/XS54

%20STRIPMICA.png)

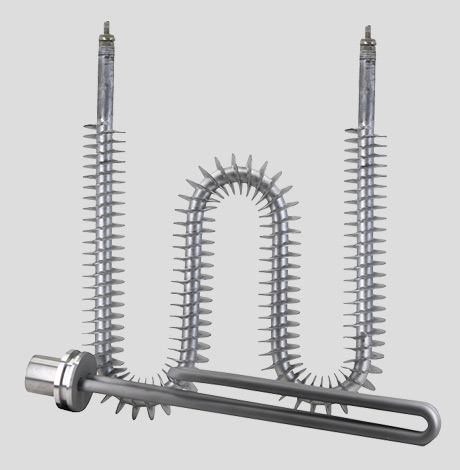

%20CERAMICINSULATEDFINNED.png)

%20(2)%20SPECIALFEATURES.png)