MARKETS

CUSTOM HEATING SOLUTIONS FOR HYDROGEN FUEL

APPLICATIONS

Backer Hotwatt is on the leading edge of the rapidly emerging hydrogen fuel cell technology market. Our broad technology, experience, and deep bench of knowledgeable engineers enable us to design custom heating solutions—based on the unique geometries, materials, and temperature requirements—of hydrogen fuel cell applications.

Powering the Future

This discussion provides an overview of hydrogen fuel cell technology and our custom heating solutions. If a particular section interests you, we have provided links to take you directly to that portion of the page.

What Is Hydrogen Fuel Cell Technology?

Fueling Clean, Sustainable Energy

Why Do Engine Systems and Components Need to Be Heated?

How We Heat Hydrogen Fuel Cell Stacks and System Components

Why Our Solutions are the Most Powerful, Flexible, and Advantageous

We Can Help Advance Your Hydrogen Fuel Cell Technology

What Is Hydrogen Fuel Cell Technology?

In the quest to find cleaner, more sustainable sources of energy, hydrogen fuel cell technology is a promising area. Hydrogen is present in water and nearly all living things. As a renewable source of energy, it has enormous potential to generate power, electricity, and heat.

The process of extracting energy is a clean, relatively simple process. Hydrogen atoms are passed through the anode of a fuel cell and stripped of their electrons. Positively-charged protons go through the membrane to the cathode and negatively-charged electrons go through a circuit and produce electricity, with water and heat byproducts of the process. Polymer electrolyte membrane fuel cells—also known as proton exchange membrane fuel cells—are primarily developed for transportation-related applications.

Fueling Clean, Sustainable Energy

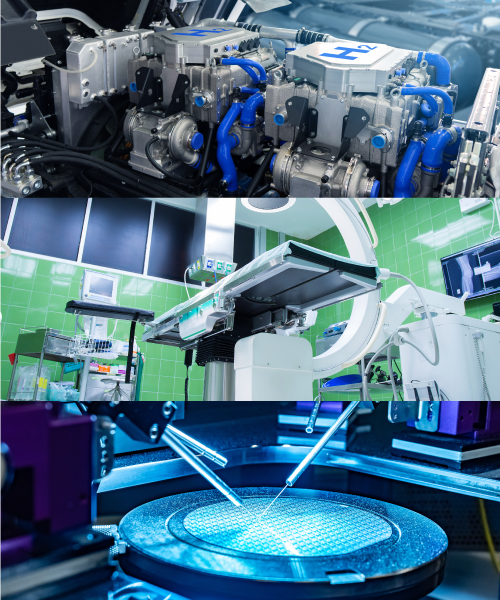

The viability and efficacy of fuel cell technology is advancing as demand for environmentally sustainable energy solutions increases worldwide. One application in particularly high demand is for hydrogen fuel cell engines to power vehicles, primarily within the commercial sector.

Hydrogen is an efficient fuel, and its many advantages include being readily available and renewable with no polluting emissions. Obstacles to widespread adoption, such as having little infrastructure in place and the expense of moving hydrogen around, will be overcome in time as new solutions are developed to meet the increasing demand.

Backer Hotwatt is at the forefront of this exciting technology, working with innovative companies to develop heaters to meet the precise requirements of hydrogen fuel cell engines.

Why Do Engine Systems and Components Need to Be Heated?

In creating hydrogen fuel cell engines for use in cold weather environments, it’s essential to bring the fuel cell stack and system components up to temperature to prevent hydrogen and water from freezing.

In temperatures above -15 degrees Celsius, passive preheating (using the system-generated heat) can be an acceptable method to bring the stack up to temperature. In environments that are less than -15 degrees Celsius, active preheating is required. One of the best methods to actively preheat the stack is to heat the system coolant.

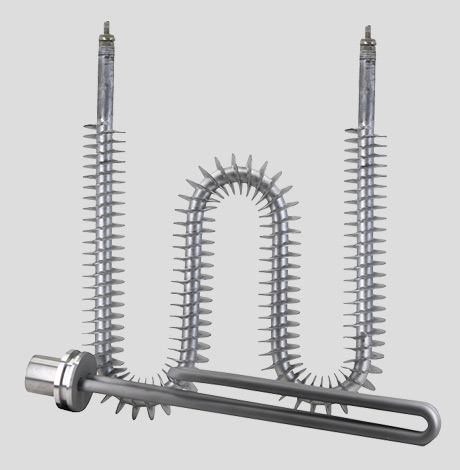

In creating hydrogen fuel cell engines for use in cold weather environments, it’s essential to bring the fuel cell stack and system components up to temperature to prevent hydrogen and water from freezing. One of the best methods to actively preheat the stack is to heat the system coolant. Backer Hotwatt designs different types of heaters based on the amount and type of coolant, time required to get the material to the target temperature, and the coolant reservoir design.

Backer Hotwatt designs different types of heaters based on the amount and type of coolant, time required to get the material to the target temperature, and the coolant reservoir design. These heaters can also perform double duty as a bleed resistor for residual energy. Other system components may also require dedicated heat sources to bring them up to temperature so that the system can work properly.

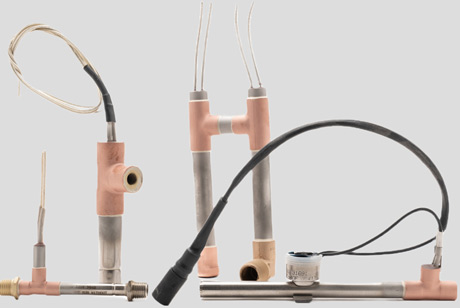

Sensor manifolds, valves, nozzles, and hydrogen gas lines may all require low-wattage heaters to boost the system performance in cold weather applications. Backer Hotwatt’s knowledgeable engineers and broad technology base enable us to design solutions based on the unique geometries, materials, and temperature requirements of each system component.

How We Heat Hydrogen Fuel Cell Stacks and System Components

Backer Hotwatt creates custom solutions for hydrogen fuel cell engines that are required to operate in challenging environments. We work closely with customers to design heaters specific to their engines’ specifications.

For engines that must be operable in environments as cold as -30 degrees Celsius, our engineers look at the fuel cell stacks, compartments, and components where liquids such as hydrogen or exhaust water may flow through or build up.

Heaters are required to keep coolant and water from freezing in hydrogen inlet and outlet lines, valves, and internal engine compartments. Our team considers many factors, including:

- Flexibility

- Adhesion

- Geometries

- Environmental conditions

- How the heater will interact with surrounding materials

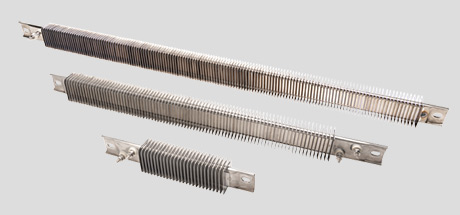

We design a variety of heaters for fuel cell engines, such as heater wire harnesses of varying lengths that are installed around inlet and transfer hoses and pipes, as well as flat silicone heaters that heat smaller areas without being invasive. Silicone heaters are ideal for compact compartments and areas that present difficult mounting options. These heaters can be made self-adhering and will lie flat on the surface for maximum heat transfer.

This cold weather heater package is designed to be a flexible solution for your unique system needs. The heater wire harnesses are rugged and can be designed and built to meet challenging size and geometry requirements

Heater wire harnesses are a rugged and highly flexible solution that can be installed on system components that have challenging sizes and geometries. Hydrogen and exhaust water that travel through valves, inlets, and port areas where ice can build up can be heated to ensure system performance and reliability.

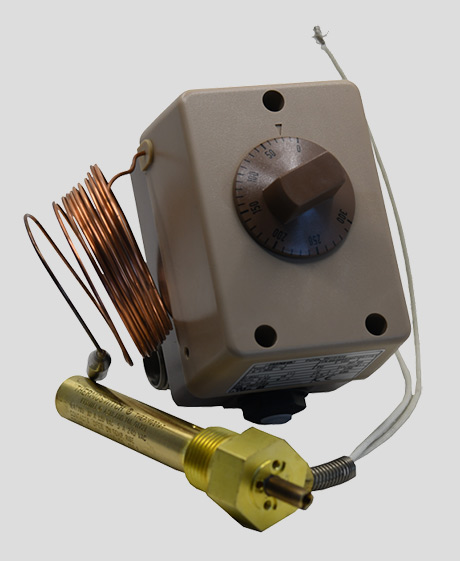

In an environment with 100 percent humidity and the potential for droplets, a check valve can be installed to ensure that air doesn’t flow back in when the engine is shut down. Thermostats can be embedded in silicone heaters to regulate temperatures and prevent overheating.

Why Our Solutions Are the Most Powerful, Flexible, and Advantageous

Backer Hotwatts’ expertise in designing and manufacturing heaters for some of the world’s most challenging applications enables us to apply our knowledge and experience to emerging technologies such as hydrogen fuel cell engines.

We work closely with our customers to develop custom solutions that meet their requirements for physical design space, performance, and reliability. Whether you are heating air, liquids or surfaces, our team of experienced engineers have the expertise to help hydrogen fuel cell and engine OEMs deliver superior performing products.

Our team is proud to help innovative companies advance their technologies and contribute to the development of sustainable energy solutions for greater efficiencies and a greener planet.

We Can Help Advance Your Hydrogen Fuel Cell Technology

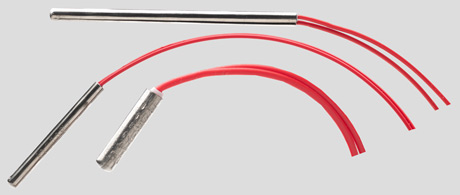

Backer Hotwatt offers the largest product line available of micro-cartridge heaters to solve difficult engineering and performance challenges. Our rugged, reliable small form factor heaters are used in a wide range of applications—from semiconductor test sockets to medical devices, and gas detection equipment to opto-electronics—any application where precision heating and reliability are paramount.

We can help you custom design and build the best heaters for your hydrogen fuel cell engine—based on the unique geometries, materials, and temperature requirements of your application. Contact an engineer today to set up an exploration consultation. We look forward to helping you soon.