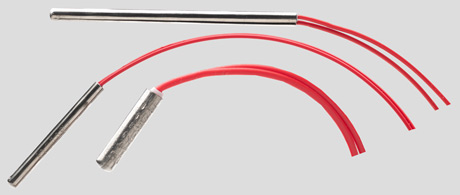

- Cartridge Heaters

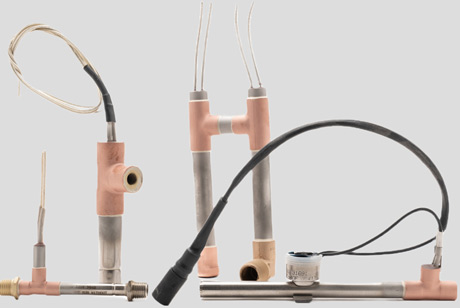

- Micro-Cartridge Heaters

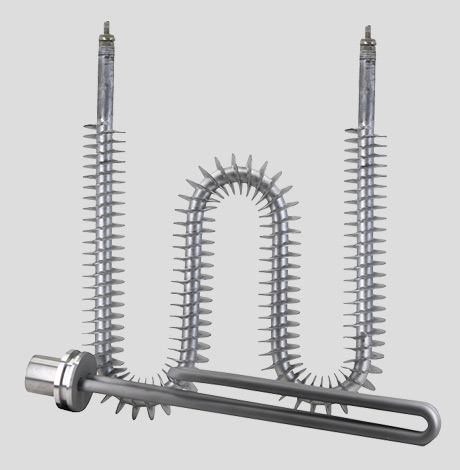

- Air Process Heaters

- Sun Rod Heater

- Tubular and Finned Tubular

- Glasrope ® & Foil Heaters

- Crankcase Heaters

- Ceramic Heaters

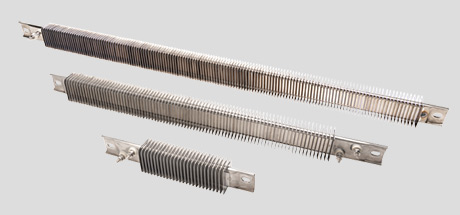

- Strip and Finned Strip Heaters

- Etched Foil and Wire-Wound Heaters

- Band Heaters

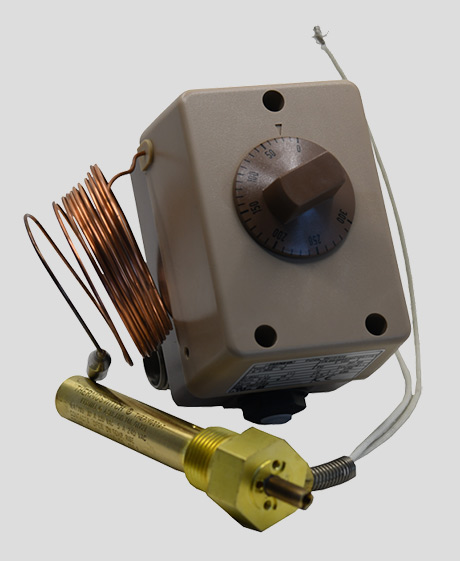

- Temperature Controlling Devices

- Miscellaneous Heaters

- Voltage Controlling Devices

- Stock Heaters

- Accessories

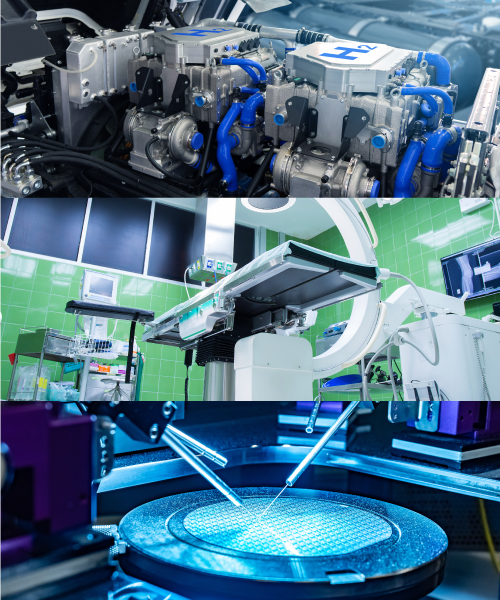

Heaters For Medical Devices

For almost 70 years, Backer Hotwatt has been working with engineers from the most

important medical equipment manufacturers from all over the world.

Custom Heating Solutions For Railroad

And Rail Transit Heating Systems

Heaters for rail switches and switch points help keep railroads and rail transit systems running 24/7.

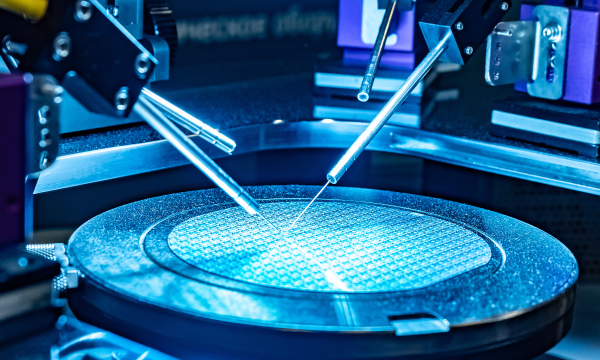

Heaters For Semiconductors

Engineers from leading semiconductor and electronics assembly companies globally have depended on Backer Hotwatt for over a half-century for precision heating and tight tolerances.

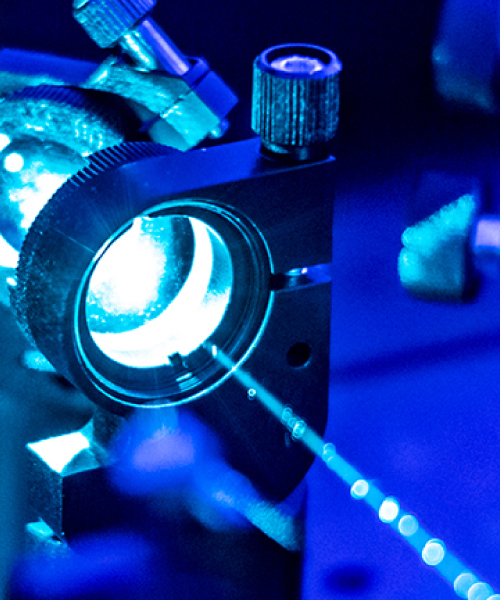

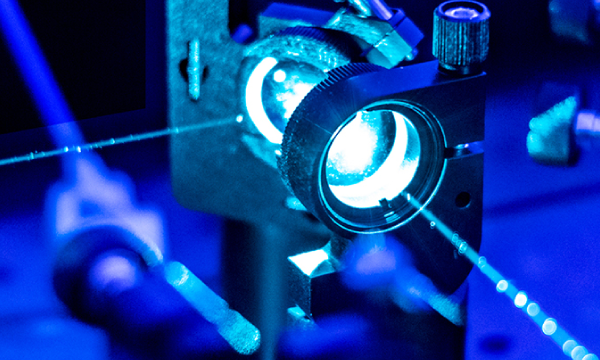

Heaters For Lasers & Optoelectronics

Increasingly, laser-based solutions are being developed to solve problems in cutting,

marking, ablation, and measuring applications.

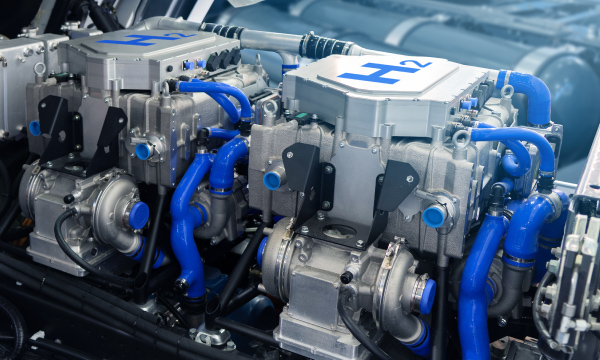

Custom Heating Solutions For Hydrogen

Fuel Applications

Backer Hotwatt creates custom solutions for hydrogen fuel cell engines that are required

to operate in challenging environments.

Scientific Instruments Market

The scientific instruments market is at the forefront of innovation, providing essential tools for research, analysis, and experimentation across a multitude of scientific disciplines, markets, and applications.

Products

- Cartridge Heaters

- Micro-Cartridge Heaters

- Air Process Heaters

- Sun Rod Heater

- Tubular and Finned Tubular

- Glasrope ® & Foil Heaters

- Crankcase Heaters

- Ceramic Heaters

- Strip and Finned Strip Heaters

- Etched Foil and Wire-Wound Heaters

- Band Heaters

- Temperature Controlling Devices

- Miscellaneous Heaters

- Voltage Controlling Devices

- Stock Heaters

- Accessories

Learn more

Connect with us

Backer Hotwatt

16A Electronics Ave

Danvers, Massachusetts 01923-1011

Tel: # (978) 777-0070

Fax: # (978) 774-2409

Contact Us

2021 Backer Hotwatt. All Rights Reserved.

2017 Backer Hotwatt. All Rights Reserved.