MARKETS

RAILROAD AND RAIL TRANSIT HEATING SYSTEMS

Railroads and rail transit systems need to keep the trains running 24/7. This requires that the rail switches and the movable rail they control—switch points—be kept free and clear of ice and snow. Frozen tracks can cause reduced travel speeds, resulting in travel disruptions. Freeze-ups can cause rail switch failure and rail signal failure, resulting in liabilities that can cause disastrous consequence. Worse, iced rails can impact the brakes’ ability to stop the train properly—the safety implications are obvious. The removal of snow and ice is best applied through direct heat to the switch points rails and the switch machines that drive them. This may also require ancillary heating of the rail ballast beneath the switch machines.

Backer Hotwatt has been manufacturing tubular heating elements for the rail and other industries for over 50 years. Backer Hotwatt’s product line fills the need for engineered, ruggedized heaters made to our customers’ specifications. These units are designed to last dependably through many seasons by using high quality materials and proprietary manufacturing techniques.

Providing Completely Customizable Heating Solutions for the Rail Industry

We excel at custom manufacturing of heaters for railways; we build heaters to any length and size, and we have the largest selection of diameters and alloys available. Because customers buy directly from us, this also means that our transit customers—both in the freight and passenger rail segments—receive better technical support and more customizable options than standard heating offerings elsewhere.

Railway Heating Products and Applications

Rail heating is segmented into varying areas listed below. You can click on the links below to go directly to the

section that interests you.

Product Specifications

Type | Length | Dia. | Terminations & Leads | Materials | Comments |

Flat Switch | < 33’ < 50’ w/splice | .355” x .670” .340” x .625” | - 6/8/10 AWG - Stainless steel sleeve w/epoxy potting - Continuous to any length - Quick disconnects | Incoloy 300 Stainless | - Available in single- or double-ended - Anti-creep collars |

Round Switch | < 33’ < 50’ w/splice | .43”/.49”/.625” | |||

Crib Heaters | Channel Length: 5’, 8’, 12’ standard Custom lengths up to 15’6” | Channel Dim: 5” width x 1.75” tall Heater Dia: .43” /.49” | - Aluminum expanded metal (mesh) cover | ||

Frog Heaters | 3’ & 12’ | .43”/.49”/.625” |

| ||

Running Rail | < 33’ < 50’ w/splice | .355” x .670” | |||

Ballast Heaters | U-bend or custom shapes | .43” /.49” | |||

Hollow Steel Tie Heaters | 7’ to 10’ | .43” /.49” | - Single-ended leads |

How can we help you with your next heating project? Contact an engineer today to set up an exploration consultation. We look forward to helping you soon.

How can we help you with your next heating project? Contact an engineer today to set up an exploration consultation. We look forward to helping you soon.

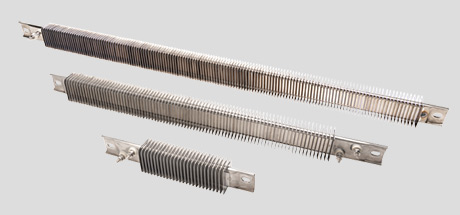

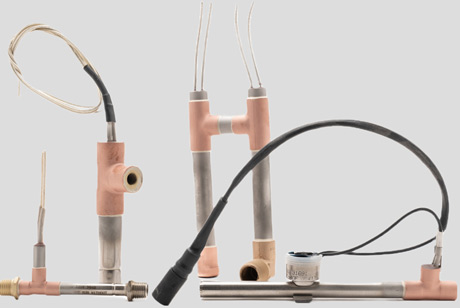

Flat Tubular Switch Point Heaters

The Hotwatt flat tubular heater delivers more heat into the rail than conventional round tubular heaters through its geometry. Flat switch point heating delivers more heat through thermal conductivity, and has ~40% surface-area contact with the rail; the round tubular heater has ~15% surface-area contact with the rail. This is constant wattage heating.

These flat switch point heaters can be placed on the outside of the running rail, with wrap-around clips through rail braces, or on the inside of the rail via bolt-on clips. These heaters are coiled for ease of transportation to the site and on the track. This switch point heater can be made of stainless steel or Inconel.

The Hotwatt flat tubular heater performs in the harshest conditions and is the most rugged and longest-lived heater on the market; this, combined with an affordable price, make it the optimal solution.

Features

- Flat tubular design, available in two profiles: .340” x .625” and .355” x .670”

- Incoloy or 300 series stainless-steel sheath materials

- Lengths to 33 feet

- Single- or double-ended terminations

- Waterproof lead wire connection with rugged stainless-steel sleeve

- Epoxy-sealed terminal-end element construction for moisture-free protection

- Mechanically crimped on protective SST sleeve at terminal connection, eliminates loosening connections from pulling of lead wire

- Custom, 6, 8, & 10 AWG

- Voltages from 120v to 750v; AC or DC

- 100 to 500 watts per feet available

- Robust in-house water and submersion testing

- Conforms to AAR specifications

- Available quick disconnects for easy element or lead replacement

- Anti-creep collars to prevent heater movement during cycling

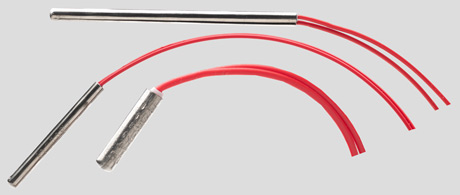

Available in a variety of lengths and diameters, the round tubular heater performs in the harshest conditions and provides a cost-effective solution to switch point heating. This constant wattage heater has ~15% surface-area contact with the rail.

These heaters can be placed on the outside of the running rail, with wrap-around clips through rail braces, or on the inside of the rail via bolt on clips. Round switch point heaters are coiled for ease of transportation to the site and on the track. This switch point heater can be made of stainless steel or Inconel.

The Hotwatt round tubular heater performs in the harshest conditions and is the most rugged and longest-lived heater on the market; this, combined with an affordable price and customization, make it the optimal solution.

Features

- Round tubular design; .430”/.490”/.625” tubular-diameters available

- Incoloy or 300 series stainless steel sheaths

- Lengths to 33 feet with no splice and up to 50 feet with splice

- Single- or double-ended terminations

- Waterproof lead wire connection with stainless-steel sleeve

- Epoxy-sealed terminal-end element construction for moisture-free protection

- Mechanically crimped-on protective SST sleeve at terminal connection, eliminates loosening connections from pulling of lead wire

- 6, 8, and 10 AWG lead wires

- Voltages from 120v to 750V; AC or DC

- 100 to 500 watts per feet available

- Robust in-house water and submersion testing

- Conforms to AAR specifications

- Available quick disconnects for easy element or lead replacement

- Anti-creep collars to prevent heater movement during cycling

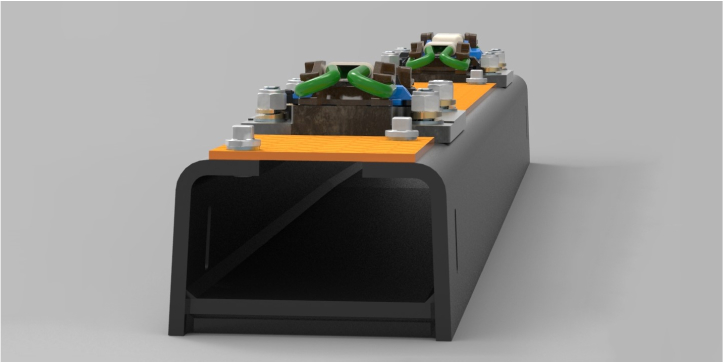

Keeping your rails free of snow and ice and allowing for unobstructed operation, crib heaters heat the switch rods, mechanisms that move the switch points from one side to the other. Easy access to the switch rods ensures proper maintenance and performance. Crib heating is especially necessary in challenge environments and harsh conditions.

The crib heater is placed directly under the switch rods on top of the rail ballast and can be attached to the rail tie to prevent any upward movement that might interfere with the switch rod operation.

The crib heaters are constructed in a hairpin construct (U-shaped) round tubular heater, such that the hairpin is placed within a cradle and held in place. The hairpin can be made of stainless steel or Inconel. The cradle, crib, is made from coated cast steel. This combination provides and extremely cost-effective solution to switch rod heating.

The Hotwatt crib heater performs in the harshest conditions and is the most rugged and longest-lived heater on the market; this, combined with an affordable price, make it the optimal customizable solution.

Standard Features

- Sturdy C-channel construction available in steel, stainless steel, or aluminum

- Slim channel design – 1 ¾ inches tall x 5 inches wide, makes installation quick and easy

- 5, 8, 12-foot standard channel lengths; custom sizes available up to 15 feet

- .430” diameter round tubular heating element, with U-bend 4-inch center-to-center

- Quick and easy installation

- Aluminum perforated guarding

- Waterproof lead wire connection with stainless-steel sleeve

- Epoxy-sealed terminal-end element construction for moisture-free protection

- Mechanically crimped on protective SST sleeve at terminal connection, eliminates loosening connections from pulling of lead wire

- 6 & 8 AWG lead wires

- Voltage 120v-600v; AC or DC

- 100 to 500 watts per feet

- Robust in-house water and submersion testing

- Conforms to AAR specifications

- Quick disconnects and mounting brackets available

How can we help you with your next heating project? Contact an engineer today to set up an exploration consultation. We look forward to helping you soon.

Movable Point Frog Heaters

A movable point frog is placed on the frog, a common crossing, to remove the gap that can exist in a fixed frog. This is usually applied to augment larger rail turnouts.

To achieve this, the frog is partially outfitted with round or flat switch point heaters; then small crib heaters are placed in between the ties under the frog for some length.

The Hotwatt frog heater system performs in the harshest conditions and is the most rugged and longest-lived heater on the market. We also excel at customization, which makes this a high-quality, affordable solution to help you meet your needs optimally.

Features

- Protective corrosion-resistant stainless steel, and rugged, durable construction performs optimally in challenging railroad environments

- 12-foot heaters for wing rails; 300 watts per foot of active heater length

- 3-foot heaters for point plates, 400 watts per foot of active heater length

- Available in 240 volts

A running rail heater is a different application of a switch point heater and can use the flat or round heater with a wrap-around clip or bolt-on clip. The heater is placed on a normal running rail, not at a switch point, and may have multiple segments to attain greater length.

Running rail heating applications are sometimes used in hump yards, inclined rail, or rail that experiences iced conditions.

Running rail heaters are manufactured with a protective corrosion-resistant stainless steel. Their rugged, durable construction performs optimally in challenging railroad environments. Best used along critical sections of the rail that require direct and consistent heat distribution to prevent ice buildup.

Standard Features

- Flat tubular design, specified to .355” x .670” dimension; provides efficient, maximum heat transfer

- Incoloy or 300 series stainless steel sheath

- Lengths to 33 feet with no splice

- Single- or double-ended terminations

- Waterproof lead wire connection with stainless-steel sleeve

- Epoxy-sealed terminal-end element construction for moisture-free protection

- Mechanically crimped on protective SST sleeve at terminal connection, eliminates loosening connections from pulling of lead wire

- Clamp design allows for expansion fluctuation without compromising contact with the rail

- #6 and #8 AWG lead wires

- Voltage 120v-600v; AC or DC

- 100 to 500 watts per feet available

- Robust in-house water and submersion testing

- Conforms to AAR specifications

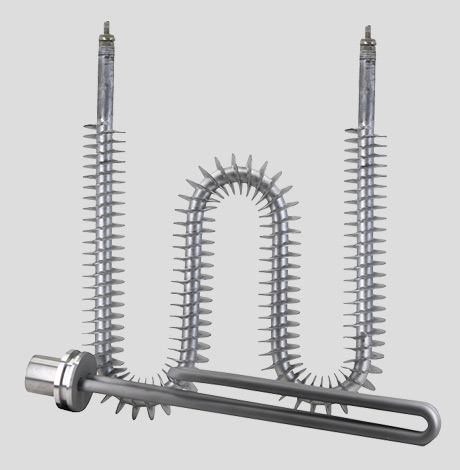

When rails require ancillary heating of the rail ballast beneath the switch machines, a ballast heater does the job. It is an application of the running rail heater and/or crib heater that is placed in the ballast rock to heat the ballast. It does not fill up the entire crib space.

The weatherproof ballast heater system performs in the harshest conditions and is the most rugged and longest-lived heater on the market; our customization, combined with an affordable price, make it the optimal solution to combat freeze-ups in unpredictable environments.

Standard Features

Hollow steel ties enable firm and reliable track infrastructure that prevents the track from giving way to the ballast, as is the case with many wooden ties—they are most typically accompanied with concrete ties. Hollow steel ties can be part of a prefabricated track segment, hollow steel ties and concrete ties, to allow for the integration of several switch machines. If the hollow steel tie is not part of a prefabricated track segment, then they are most typically, but not exclusively, put in place with concrete ties vs. wood ties.

The switch machine rods are placed in hollow steel ties, which provides for maximum protection of the rods. To heat the switch rods, a heater channel is placed on each inner side of the hollow steel tie to allow for a switch heater to be inserted (two per hollow steel tie per each rod; four hollow steel tie heaters). There are typically two heated hollow steel ties per switch machine. Note, there are also rotary-assist linkages that require heating: these require one hollow steel tie and two hollow steel tie heaters.

This is the most efficient way of heating switch rods and linkages that are integrated into the hollow steel tie; this totally mutes degradation of heat due to wind.

Another benefit of the hollow steel tie construct is cable management. Since the ties are hollow, it is easy to pass cabling through the ties without trenching below the ballast, using a conduit system to pass cabling to the other side of the track.

Many hollow steel tie manufacturers provide the channel assembly with a thermowell to accept a heater. If a channel assembly is not installed, Backer Hotwatt can provide the entire assembly along with the heater. These heaters are typically 7 to 10 feet long and are between 100 and 200 watts per foot.

How can we help you with your next heating project? Contact an engineer today to set up an exploration consultation. We look forward to helping you soon.

Customized Railway Heaters for Transit Requirements

Precision heating, tight tolerances, and extreme reliability are all characteristics that need to be custom designed into solutions for your critical applications. You can be assured that Backer Hotwatt engineers will work in close collaboration with your team to meet all performance, physical, and regulatory requirements to ensure a successful product launch and commercialization.

Backer Hotwatt solves challenging problems with unique solutions that our competitors won’t or can’t provide. We’re here to help you design and manufacture the best heater for your demanding and precise needs. We excel at custom manufacturing of heaters for railways. This means:

- We build heaters to any length and size

- We have largest selection of diameters and alloys available

- Transit customers—both in the freight and passenger rail segments—buy directly from us

- You receive better technical support and more customizable options than standard heating offerings elsewhere

How can we help you with your next heating project? Contact an engineer today to set up an exploration consultation. We look forward to helping you soon.